Description

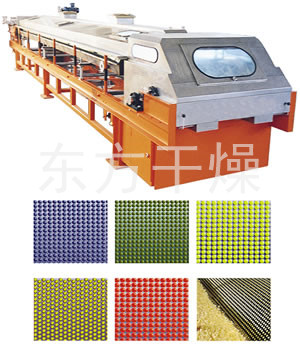

RL granulator is a melting point below 250 ℃ features use of materials, according to scope of viscosity of the molten state through a special cloth The apparatus was uniformly melted at constant speed below the strip, the cooling effect of a continuous strip placed below the spraying means, so that the material transport, shift operation process has been cooled and solidified, the packaging, so as to achieve granulation the purpose of forming.

The apparatus was uniformly melted at constant speed below the strip, the cooling effect of a continuous strip placed below the spraying means, so that the material transport, shift operation process has been cooled and solidified, the packaging, so as to achieve granulation the purpose of forming.

Features

This product is a new (meltable) molding granulator. A thin strip heat and atomized spray cooling the molten liquid rapid curing, using single rotating shell. So easy maintenance, wear very little, and high productivity. Handling and quick replacement product. And strip off the molding machine and high-speed synchronous operation which can produce uniform ingot grain, improve productivity and increase production profits. And can eliminate dust, improve the environment, significantly expanded the range of viscosity. The product is an economical and reliable production process, the particles can be processed Φ4-12mm these products is very uniform, hemispherical, strip and sheet, stable, non-thermal stresses are high quality and purity. Since the device comes with a filter - blocking means more reliable operation.

Structure (1)

Processed products based on the melting point (freezing point), different material viscosity and temperature of the cooling effect, to choose the speed of transport and head speed, so as not to affect the production capacity and granular quality.

The aircraft from liquid to solid particulate, mainly through the granulation die granulation using rotary continuous strip, by spraying water cooling stereotypes.

Structure (2)

It consists of blanking die forming granulation head, stainless steel cooling conveyor belt and pulleys, spray cooling system, transmission system, heat-retaining device, rack, blade and other components. Blanking die pelletizing head mainly by the head die head spindle sleeve and other components. Spray cooling system consists of nozzle, filled ponds and other components. Transmission mainly by the reduction gearbox (gear unit) speed motor and other components.

Adapt materials

This product is suitable for melting point (or softening point) at 50 ℃ -300 ℃ desired granulation of various materials, as well as "cold crystallization" of material properties.

Skills requirement

Material must not be filtered solid impurities into the granulation head, otherwise it will cause head wear or blockage, affecting the quality of the granulation.

Temperature control should be based on the melting temperature to be, insulation requirements temperature must not exceed ± 3 ℃. The cooling system should be added to the filter, the cooling water temperature is generally between 5 ℃ -25 ℃ (low temperature, rapid prototyping, granular good, high yield).

Outline

his product is a new (meltable) molding granulator. Work by the cooling liquid through the delivery becomes solid, melting point range in the material of 50 ℃ ~ 300 ℃ can be granulated molding. No dust, improve the production environment; and a certain economic value (energy saving, economical packaging containers), fast product replacement, pelletized product beautiful, even nearly hemispherical granular, no heat stress; granular product is both easy packing, transport, storage , and user-friendly measuring, mixing or remelting, continuous production. Fed from the packaging, reduce manual labor, with stepless adjustable flow, easy to operate. Widely used in petroleum, chemical and other industries. A machine-made strips, diced, sheet; toxic materials can be used for closed-type group.

Technical Specifications

| Model | RL60-A | RL60-B | RL60-C | RL60-D | RL120-A | RL120-B | RL120-C | RL120-D |

| The effective heat transfer area(m2) | 2.6 | 3.6 | 4.6 | 5.3 | 7.3 | 9.3 | 10.8 | 16.6 |

| Primary / secondary motor power(kw) | 1.5/0.75 | 1.5/0.75 | 1.5/1.1 | 1.5/1.1 | 3/1.5 | 3/1.5 | 3/1.5 | 4/2.2 |

| Dimensions(mm) |

5600×1200 ×1800 |

7200×1200 ×1800 |

8800×1200 ×1800 |

10050×1200 ×1800 |

7200×1700 ×1800 |

8800×1700 ×1800 |

10050×1700 ×1800 |

14800×1700 ×1800 |

| Production capacity(kg/h) | 80-100 | 100-150 | 120-180 | 150-250 | 300-380 | 360-420 | 380-500 | 500-800 |

| Total weight(kg) | 1360 | 1580 | 1880 | 2060 | 2380 | 2590 | 2830 | 4210 |