Product description

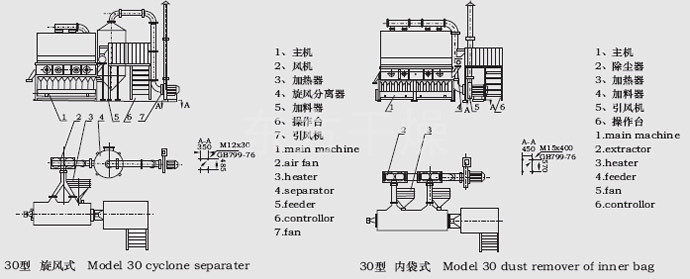

Boiling dry, also known as fluidized bed, which consists of air filter, heater, boiling bed, cyclone separator, bag filter, high pressure centrifugal fan,  Operation table, due to the different nature of the dried materials, ancillary equipment when dust, may need to be considered, which can select cyclone separator, bag filter, can also choose one of the general and specific gravity larger particles such as granules simply select material drying cyclone, the proportion of lighter granular and powdered materials required supporting bag filter, and equipped with pneumatic feeding device and belt conveyor for selection.

Operation table, due to the different nature of the dried materials, ancillary equipment when dust, may need to be considered, which can select cyclone separator, bag filter, can also choose one of the general and specific gravity larger particles such as granules simply select material drying cyclone, the proportion of lighter granular and powdered materials required supporting bag filter, and equipped with pneumatic feeding device and belt conveyor for selection.

Loose granular solid material from the fluidized bed dryer feeder, clean filtered air heated by the blower into the bottom of the fluidized bed through distribution plate in contact with the solid material to form a gas-solid fluidized state heat and mass transfer. After drying the material is discharged from the discharge port, the exhaust gas discharged from the top of the fluidized bed by the cyclone and bag filter group recovered solid powder emptying.

Steam, electricity, hot air furnace can be used (as request).

Working principle

Clean and hot air through the valve plate distribution into the bed body, forming boiling from the feeder into the wet material to be hot air. Since the hot air with the material extensive contacts and enhanced heat and mass transfer process, so in a relatively short period of time it can be dried. As with the continuous material into the body from a bed, several minutes, boiling dried automatically flows out from the other side of the bed. This equipment is generally negative pressure operation.

Adapt materials

◎ Medicines, chemical raw materials, food, food processing, feed drying operation. Such as: raw material medicine, tablet granules, Chinese traditional medicine, health food, beverage powder, corn germ, feed, resin, citric acid and other powder materials dry desiccant. Materials suitable particle size is generally 0.1 ~ 6mm, the optimum particle size of 0.5 ~ 3mm.

Installation Notes

◎ All equipment should be placed flat, foot fixing screws, the components sealed well.

◎ fan can be placed in the outdoor or indoor self-built silencer. Layout can be adjusted as appropriate depending on the circumstances.

Technical Parameters

|

Specifications Model Technical Parameters |

XF0.25-1 (Original XF10) |

XF0.25-2 (OriginalXF20) |

XF0.25-3 (OriginalXF30) |

XF0.25-6 | XF0.3-2 | XF0.3-4 | XF0.3-6 | XF0.3-8 | XF0.3-10 | XF0.4-4 | XF0.4-6 |

| Bed area(m2) | 0.25 | 0.5 | 1.0 | 1.5 | 0.6 | 1.2 | 1.8 | 2.4 | 3.0 | 1.6 | 2.4 |

| Drying capacity(kg h2O/h) | 10-15 | 20-25 | 30-45 | 52-75 | -30 | 42-60 | 63-90 | 84-120 | 105-150 | 56-80 | 84 |

| Fan power(kw) | 5.5 | 7.5 | 15 | 22 | 7.5 | 18.5 | 30 | 37 | 48 | 30 | 37 |

| Inlet air temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

| Dimensions (host) length × width × height(m) | 1×0.6 | 2×0.6 | 4×0.6 | 6×0.6 | 2×0.70 | 4×0.7 | 6×0.7 | 8×0.7 | 10×0.7 | 4×1 | 6×1 |

| Covers(m2) | 18×3.35 | 25×3.35 | 35×3.35 | 40×3.35 | 25×3.4 | 38×3.4 | 45×3.4 | 56×3.4 | 70×3.4 | 18×3.58 | 56×3.58 |

|

Specifications Model Technical Parameters |

XF0.4-8 | XF0.4-10 | XF0.4-12 |

XF0.5-4 (OriginalXF50) |

XF0.5-6 | XF0.5-8 | XF0.5-10 | XF0.5-12 | XF0.5-14 | XF0.5-16 | XF0.5-18 |

| Bed area(m2) | 3.2 | 4.0 | 4.8 | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 7.0 | 8.0 | 9.0 |

| Drying capacity(kg h2O/h) | 112-160 | 140-200 | 168-240 | 70-100 | 140-200 | 140-200 | 175-250 | 210-300 | 245-350 | 280-400 | 315-450 |

| Fan power(kw) | 44 | 66 | 66 | 30 | 66 | 66 | 90 | 90 | 150 | 150 | 165 |

| Inlet air temperature(oC) | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 | 120-140 |

| Material temperature(oC) | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 | 40-60 |

40-60 |

40-60 | 40-60 | 40-60 |

| Dimensions (host) length × width × height(m) | 8×1 | 10×1 | 12×1.2 | 4×1.2 | 8×1.2 | 8×1.2 | 10×1.2 | 12×1.2 | 14×1.2 | 16×1.2 | 18×1.2 |

| Covers(m2) | 74×3.58 | 82×3.58 | 96×4.1 | 50×4.1 | 70×4.1 | 82×4.1 | 100×4.1 | 140×4.1 | 180×4.1 | 225×4.1 | 268×4.1 |

Note: a feeding mode: 1 star feeding; 2 star formula feeding and pneumatic conveying with; belt conveyor 3; 4 user-definable.

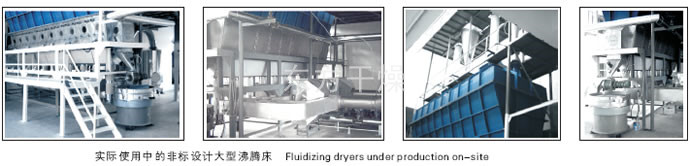

II. Production can be automated. III. In addition to these models, users can make special design. IV. Depending on the material, fan power is also different.

Schematic