Product description

The product can paste, granules, powders, slurries indirect heating or cooling can be accomplished drying, cooling, heating, sterilization, reaction, low temperature combustion unit operation. Devices special wedge stirring blade has a higher heat transfer efficiency of heat transfer and heat transfer surfaces self-cleaning function.

Working principle

Hollow shaft densely arranged hollow wedge-shaped blade, axial flow through the heat medium through the hollow blades. The effective heat transfer area per unit volume is large, heat medium temperature from -40 ℃ to 320 ℃, may be water vapor, liquid type may be: hot water, oil and the like. Indirect conduction heating, no air to carry away the heat, the heat was used to heat the material. Insulation heat loss to the environment only by body heat. Wedge-shaped blade having a heat transfer surface self-cleaning function. Particles and relative movement of the wedge-shaped surfaces to produce wash effect, can wash away the surface of the wedge-shaped attachment material, so that the operation has maintained a clean heat transfer surfaces. Blade dryer is Ω type of housing, housing the general arrangements for two to four hollow stirring shaft. Housing seal cover and cover to prevent dust escaping material fully play its role.

A heat transfer medium through the rotary joint, flowing in the casing jacket and hollow stirring shaft, stirring hollow shaft according to the type of heating medium having a different internal structure, to ensure optimum heat transfer.

Features

◎ blade dryer is low energy consumption: Due to the indirect heating, not a lot of air to carry away the heat, the outer wall of the dryer and set the insulation layer of slurry material, evaporated water only 1.2kg 1kg water vapor.

◎ blade dryer is low cost system: has a huge heat transfer surface per unit effective volume, shortening the processing time, the device size becomes smaller. It greatly reduces the floor space and building space.

◎ wide range of materials handling: Use a different medium heat, can deal with heat-sensitive materials, but also need to deal with the high temperature treatment of materials. Common media are: steam, thermal oil, hot water and cooling water.

Continuous operation can also be intermittent operation can be applied in many fields.

◎ environmental pollution: do not use carry air, dust material entrained very little. Material solvent evaporation is very small, easy to handle. Of contaminated material or solvent to be recovered condition, can be used

Closed cycle.

◎ operating costs low: the structure. A small amount of wear, maintenance costs low.

◎ stable operation: Due to the wedge-shaped blade special compression - expansion stirring, so that the material particles are sufficiently in contact with the heat transfer surface in the axial zone, material temperature, humidity, mixing gradient is very small, thus ensuring the process stability.

Adapt materials

Paddle dryer has been successfully used in the food, chemical, petrochemical, dyes, industrial sludge and other fields. Heat transfer equipment, cooling, stirring so that the characteristics of the operation unit can perform the following: combustion (low-temperature), cooled, dried (solvent recovery) heating (melting), the reaction and sterilization. Stirring blades is also the heat transfer surface, so that the heat transfer area per unit effective volume is increased, the processing time is shortened. Wedge-shaped blade heat transfer surface and having a self-cleaning function. Compression - expansion of the material mixture evenly mixing function. Material axially into a "plug flow" movement in the axial zone, material temperature, humidity, mixing gradient is very small. Used to do medium heat blade dryer low temperature combustion can be accomplished work. Such as: calcium sulfate dihydrate (Ca2SO4 · 2H2O) combustion into calcium sulfate hemihydrate (Ca2SO4 · 1 / 22H2O). Sodium bicarbonate (NaHCO3) into calcined soda (Na2HCO3) and the like. Pass into a cooling medium, such as water, salt water, etc. can be used to cool the cooling. Such as: used in the soda ash industry paddle cooler base machine, replace the old air-cooled cooler base machine, energy saving and exhaust gas treatment equipment, reducing operating costs. Drying, the main function of the device, do not use hot air, the solvent recycling, energy consumption, environmental control in the ideal state tractable. To be recovered solvents, flammable material is particularly heat-sensitive oxide adaptation. It has been widely used in chemical, petrochemical and dye industries. Axial area, temperature, humidity, degree of mixing uniformity, so that the device can be used to heat or melt, some of the solid material or the reaction. It has been successfully used in the fertilizer industry and modified starch. Blade dryer can be used for sterilization of food and flour. Unit effective volume of large heating area, will soon be heated to the sterilization temperature, avoiding prolonged heating to change the quality of materials.

Technical Specifications

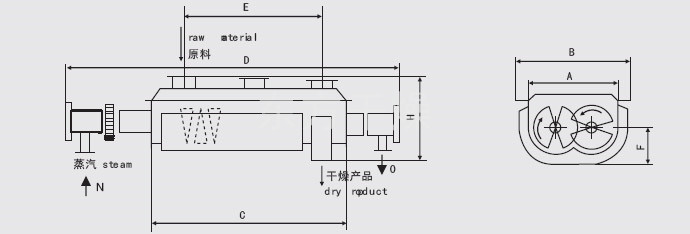

|

Project Model |

KJG3 | KJG9 | KJG13 | KJG18 | KJG29 | KJG41 | KJG52 | KJG68 | KJG81 | KJG95 | KJG110 |

| Heat transfer area(m2) | 3 | 9 | 13 | 18 | 29 | 41 | 52 | 68 | 81 | 95 | 110 |

| Effective volume(m3) | 0.06 | 0.32 | 0.59 | 1.09 | 1.85 | 2.8 | 3.96 | 5.21 | 6.43 | 8.07 | 9.46 |

| Speed range(rmp) | 15-30 | 10-25 | 10-25 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 5-15 | 5-15 | 5-10 |

| Power(kw) | 2.2 | 4 | 5.5 | 7.5 | 11 | 15 | 30 | 45 | 55 | 75 | 95 |

| Body width A(mm) | 306 | 584 | 762 | 940 | 1118 | 1296 | 1476 | 1652 | 1828 | 2032 | 2210 |

| Overall width B(mm) | 736 | 841 | 1066 | 1320 | 1474 | 1676 | 1854 | 2134 | 1186 | 2438 | 2668 |

| Body width C(mm) | 1956 | 2820 | 3048 | 3328 | 4114 | 4724 | 5258 | 5842 | 6020 | 6124 | 6122 |

| Overall Length D(mm) | 2972 | 4876 | 5486 | 5918 | 6808 | 7570 | 8306 | 9296 | 9678 | 9704 | 9880 |

| Access to materials E(mm) | 1752 | 2540 | 2768 | 3048 | 3810 | 4420 | 4954 | 5384 | 5562 | 5664 | 5664 |

| Center height F(mm) | 380 | 380 | 534 | 610 | 762 | 915 | 1066 | 1220 | 1220 | 1220 | 1220 |

| Total height H(mm) | 762 | 838 | 1092 | 1270 | 1524 | 1778 | 2032 | 2362 | 2464 | 2566 | 2668 |

| Intake port N(Inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |

| Outlet O(Inch) | 3/4 | 3/4 | 1 | 1 | 1 | 1 | 11/2 | 11/2 | 11/2 | 11/2 | 2 |